Products » Equipment » Compressors

The most advanced design for the utmost reliability

The most advanced design for the utmost reliability

Designed and manufactured to meet the most demanding requirements of industrial refrigeration and energy recovery, this compressor offers high perfomance and reliability with low operating and maintenance costs. Suitable for operation with all refrigerants, available in 4 models: 4, 6, 8 and 12 cylinders.

Built with decades of refrigeration compressor producing know-how this hight capacity and energy efficient machine has met the test of time through experience of a full range of applications in thousands of installations the world over.

Extremely robust, low noise level even at the highest speeds of rotation, incomparable simplicity of construction and maintenance, all of which constitute the best guarantee for maximum reliability of your plant.

Double Oil Separation

The traditional separators have been replaced with our double oil separation system, providing a more rapid and economic installation with reduced maintenance.

The oil consumption is negligible under 0.025 gr/HP/h.

Cooling System

Designed to operate with all refrigerants at the most severe pressure and temperature conditions, the machine is preset for an effective head cooling by water circulation, thus also keeping at lower level the working temperature with consequent longer life of valves.

The oil cooling, when required, is carried out by an external water cooled oil cooler.

Lubricating Circuit

Oil pump arranged for both directions of rotation: double filtering system; full flow oil circulation through the crankshaft and the shaft seal box, for efficient heat removal.

Minimum load start and capacity control

Standard steps of factory installed capacity reduction with hydraulically actuated cylinder unloading (unloaded start device supplied on request).

Standard Capacity Control Steps Single Stage.

The position 0% is used for the unloaded start.

| Cyl. No. | Percent of full Load | ||||

| 4 | 100 | 50 | 0 | ||

| 6 | 100 | 66 | 33 | 0 | |

| 8 | 100 | 75 | 50 | 25 | 0 |

| 12 | 100 | 66 | 33 | 0 | |

Acceptance Tests

All the compressors are hydraulically and pneumatically tested.

Before shipment, the compressors, complete with the ordered accessories, are final-tested for 24 hours.

Test certificates, according to the Standards of International Classifi-cation Boards, are furnished upon request for all models.

Operatevg Conditions

All the Series PMI 125 X 90 compressors operate at a maximum speed of 1500 rpm, with application range up to a differential pressure value of 14 kg/cm2.

Maintenance

The exceptionally easy accessibility of all internal parts, together with the simplicity of compressor design, permits a rapid and thus economic maintenance.

Technical Data

|

|

Single Stage Reciprocating Compressors

| Model | Swept Vol. M3/h |

Befrigeration Capacity and Absorbed Power | Dimensions mm. |

|||||

| NH3 | R22 | |||||||

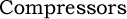

| Kcal/h | BkW | Kcal/h | BkW | A | B | C | ||

| PMI 125 X 90 - 4 | 390 | 160900 | 60.9 | 148800 | 61.0 | 900 | 850 | 685 |

| PMI 125 X 90 - 6 | 585 | 243750 | 92.3 | 225400 | 95.5 | 945 | 850 | 765 |

| PMI 125 X 90 - 8 | 780 | 321750 | 122.7 | 297500 | 123.0 | 1.350 | 850 | 685 |

| PMI 125 X 90 - 12 | 1.170 | 482600 | 184.6 | 446300 | 185.0 | 1.440 | 850 | 1.035 |

Single Stage Reciprocating Compressors

| Model | Swept Vol. M3/h |

Befrigeration Capacity and Absorbed Power | Dimensions mm. |

||||||

| NH3 | R22 | ||||||||

| LP | HP | Kcal/h | BkW | Kcal/h | BkW | A | B | C | |

| PBI 90 - 6 - ID | 388.6 | 139.2 | 45200 | 36.5 | 48300 | 42.0 | 1.045 | 820 | 905 |

| PBI 90 - 6 - IS | 388.6 | 139.2 | 51800 | 37.4 | 61500 | 44.1 | 1.045 | 820 | 985 |

| PBI 90 - 8 - ID | 583.6 | 139.2 | 61000 | 50.5 | 67500 | 57.1 | 1.460 | 850 | 925 |

| PBI 90 - 8 - IS | 583.6 | 139.2 | 70800 | 50.8 | 80600 | 57.8 | 1.460 | 850 | 925 |

| PBI 90 - 12 - ID | 777.2 | 278.2 | 90400 | 73.0 | 96600 | 84.0 | 1.470 | 850 | 1.035 |

| PBI 90 - 12 - IS | 777.2 | 278.2 | 103600 | 74.8 | 123000 | 88.2 | 1.520 | 850 | 1.035 |

ID: Integrated Intermediate Gas Desuperheating System.

IS: Integrated Intermediate Gas Desuperheating with Liquid Subcooling

Swept volume and capacity ratings are based on the following conditions:

speed 1470 rpm; for the single stage tss, - 10° C, tsd + 40°C; and two stage tss 40° C.', tsd + 40°C;